From the beginning, Moana was destined to be a unique vessel. It was a power catamaran, built to a design and composite materials relatively new to boatbuilding, and specifically built to cross oceans and operate in remote locales for extended periods of time. There would be no support services in those faraway lands, so the engineering and construction had to be first class. This began with a design by a consortium of talented people in New Zealand, and built in San Diego by my company, “Compass Rose International.”

A boat, an airplane, or even a bridge is only as strong as its weakest member, so a world-renowned company was tasked with engineering the size of all the structural components and every layer of carbon fiber or fiberglass. This produced a remarkably light but very strong structure. Completed by my crew of very talented professionals, Moana combined strength, function, and class to become the perfect vessel for an extraordinary dream.

Typical bulkhead construction with high-density foam frames attached to the hull. When completed with inboard panel, this bulkhead leads down to an aft cockpit and access to the sea, where Elena is quite pleased with her dad for rescuing a turtle. Trapped in discarded fishing gear, he was exhausted to the point of drowning so we brought him aboard to rest. Note white lines on flippers and on edge of shell, where the lines tangled and abraded the skin.

Pilothouse helm area taking shape. Operational in Cayo Largo, Cuba, and with cook Susie on watch, offshore Western Australia. All of the sophisticated electronics in these photos were destroyed by a lightning strike in Nicaragua.

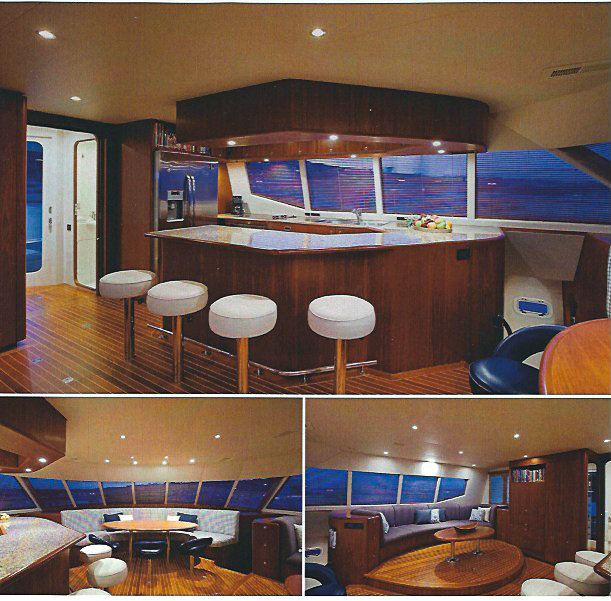

Main cabin salon, with dining area (looking fwd). Note carbon fiber (black) used for high strength reinforcing. Galley to port. Michel leading family, guests, and cook in gourmet Asian seafood dinner.

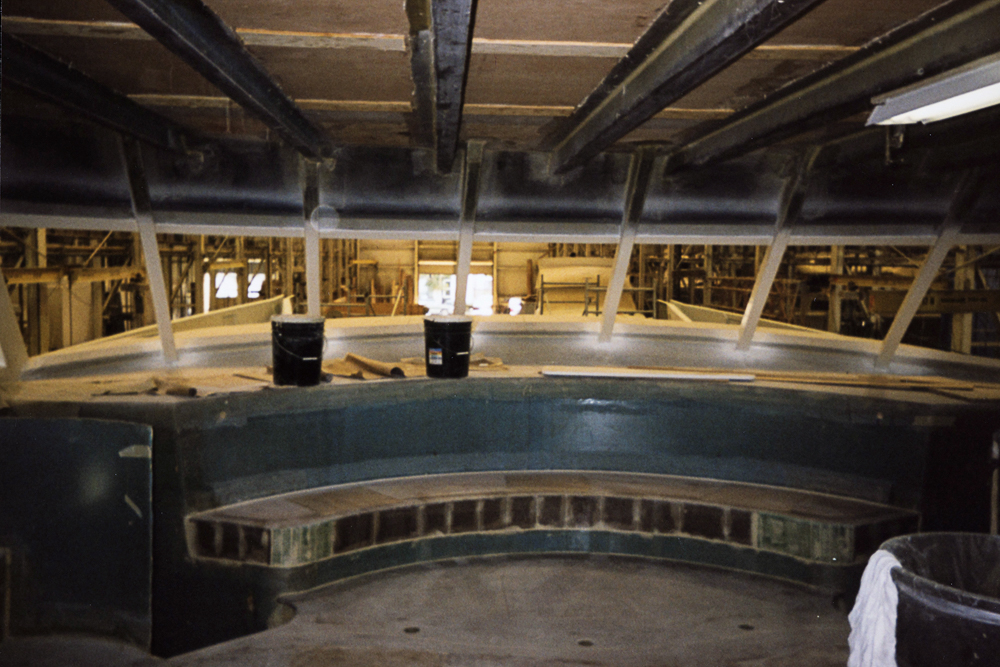

Salon entertainment area to stbd, carpenter building settee seating, and finished galley and dining area. Note granite countertop, beautiful golden teak used in final cabinetry, teak and ash wood floors. Combination photo was taken after 13 years of cruising, a testament to the loving care and maintenance over the years.

Master cabin build out. From raw fiberglass to beautiful teak veneer and lovely décor. 5-Star in every way!

VIP guest stateroom, to port. Note upper and lower hull stiffeners in first photo, cleverly concealed with final construction. All fuel and water carried in integral tanks below floors in cabins. This feature ensured a very low center of gravity, making it impossible to capsize the vessel.

Lanai (aft) deck, looking to stbd. Note stairwell to pilothouse, elegant curved sliding door, teak deck, and deck freezer (far right). This was a favorite outdoor dining/gathering place such as when Jean-Pierre weighed up this 200 lb. Yellowfin tuna, caught at Clipperton Island.

From an empty skeleton, to moving day. From a dark boat yard building to showing her stuff in bright sunshine, it was a big day for the crew and me. We had to cut away part of the building to move her out. Last photo at dock in Petersburg, Alaska.